ANODIZED

Top wall prefabricated building materials

WORK REPORT

Foreword

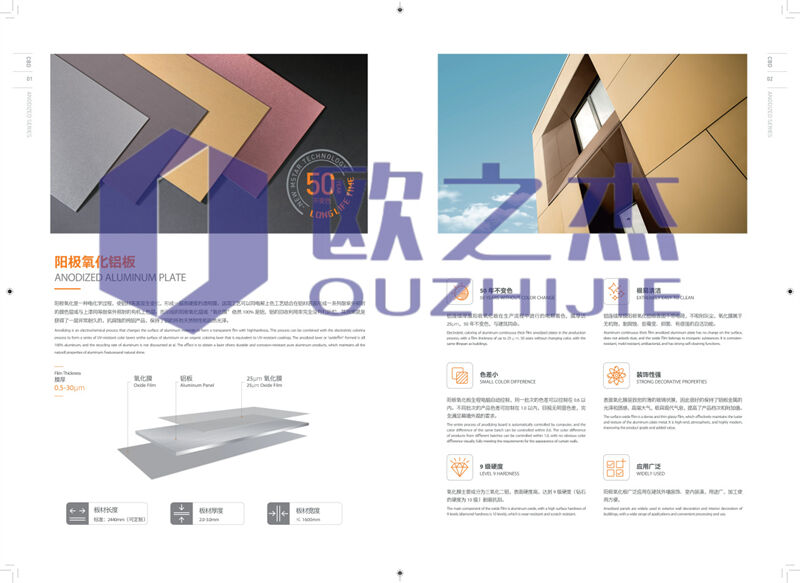

Anode oxidation is an electrochemical process that alters the surface of aluminum materials, forming a transparent film with high hardness. This technique can be combined with electrolytic coloring processes to create a series of color layers resistant to ultraviolet external irradiation on the aluminum surface or organic coloring layers with equivalent UV resistance to painting.

Anode oxidation process

The anode oxide layer or "oxide film" formed through the electrochemical process remains 100% aluminum, with no compromise in aluminum's recyclability. The result is a highly durable, corrosion-resistant pure aluminum product that retains all the natural characteristics and luster of aluminum.

Anode alumina plate has a fire rating of Class A.

A comparison between Class A fire-resistant metal composite panels and several commonly used panels on the market at a combustion temperature of 1200°C.

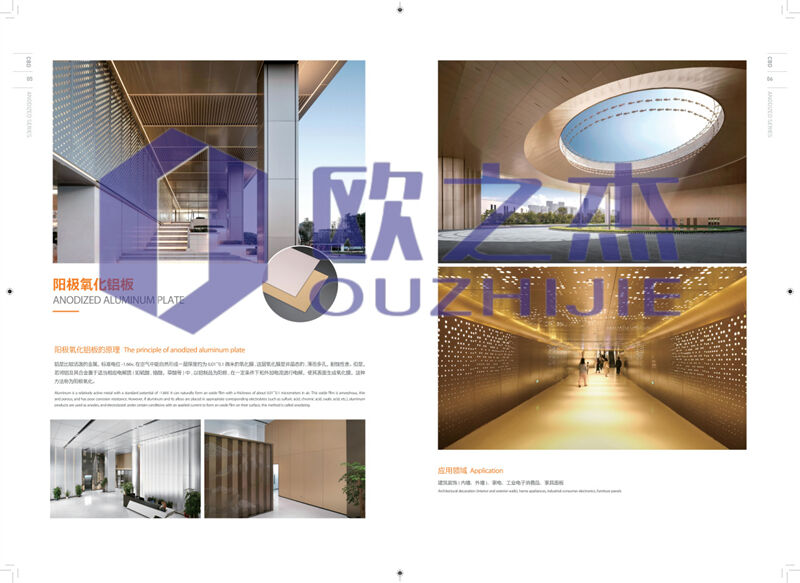

Anode oxidation principle

Aluminum is a relatively active metal with a standard potential of -1.66V. In the atmosphere, it naturally forms an oxide film with a thickness of approximately 0.01~0.1 micrometers. This oxide film is amorphous, thin, and porous, exhibiting poor corrosion resistance. However, if aluminum and its alloys are placed in an appropriate corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) with the aluminum product serving as the anode, and electrolysis is conducted under certain conditions with an external current to generate an oxide film on its surface, this method is called anodic oxidation.

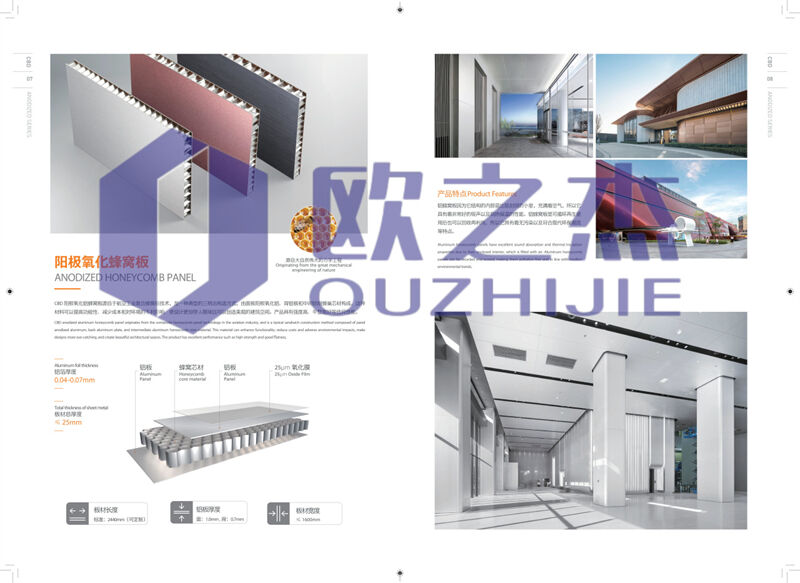

Anode alumina honeycomb panels originate from the aerospace industrial composite honeycomb panel technology, representing a typical sandwich construction method composed of an anode alumina face sheet, an aluminum back sheet, and an aluminum honeycomb core material. This material enhances functionality, reduces costs and adverse environmental impacts, creates more eye-catching designs for Homo sapiens, and enables aesthetically pleasing architectural spaces. The product boasts high strength, excellent flatness, and superior performance characteristics.

Anode oxidation plate application

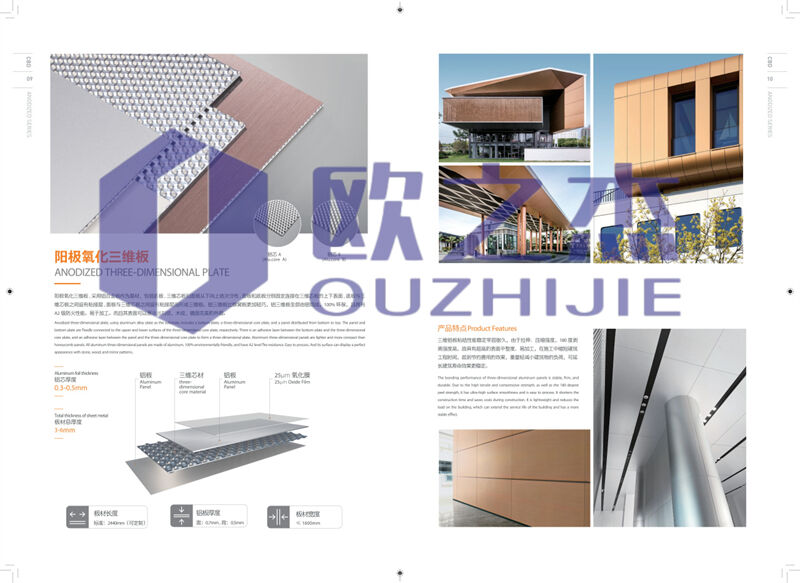

Anode-oxidized three-dimensional panel, using aluminum alloy plate as the base material, consists of a bottom plate, three-dimensional core plate, and top plate arranged sequentially from bottom to top. The top plate and bottom plate are respectively fixedly connected to the upper and lower surfaces of the three-dimensional core plate, with an adhesive layer between the bottom plate and the three-dimensional core plate, and another adhesive layer between the top plate and the three-dimensional core plate to form the three-dimensional panel. Aluminum three-dimensional panels are lighter than honeycomb panels, entirely composed of aluminum, 100% environmentally friendly, and possess A2-grade fire resistance. They are easy to process and can exhibit perfect surface appearances such as stone patterns, wood grains, and mirror finishes.

Hot News

Hot News2026-01-27

2026-01-24

2025-12-02

2025-08-05

2025-08-04

2025-08-01