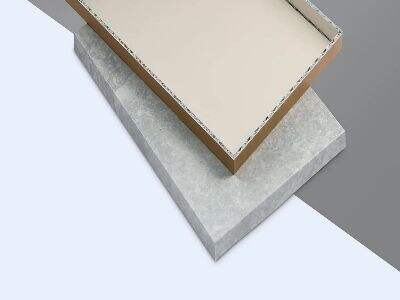

In the making of the aluminum composite panels, quality control plays a critical role in enabling final product uniformity and reliability. Pufeier, as a professional manufacturer of the industry, is proud of using strict quality control system to keep high production process. From material to final product, from inspection to test, the company will follow up and satisfy you require at any time.

How Aluminum Composite Panel Manufacturers Do Quality Control With aluminum?

It is not a particularly disadvantageous step for production of panel aluminium composite quality control, provided that it includes some system checks and forms to be filled. At Pufeier, we select the raw material from reliable suppliers to help ensure quality and consistency. We ensure the quality of every part that comes to our factory by strict material inspection, thus it reliably supports you when you process. QC-checkpoints for accuracy, surface finish and structural soundness have been strategically placed in its production process. And lastly, all finished products undergo testing and inspection ensuring every product delivered to your state-of-the- kitchen is of the upmost quality.

Key Factors

Precision engineering, state of the art technology, skilled work force, and stringent quality control are the major strength factors in aluminum composite panel production. Pufeier allocates the most advance equipment and tools to get better production running and quality. Our team of expert engineers and machinists take great pride in the production process, from design to delivery. We follow industry norms and best practices which help us maintain quality and trust with our customers thus, Steel Core maintains the consistency in our aluminum composite panels.

The Importance of Consistency in the Production of Aluminum Composite Panels

Uniformity is key in the production of aluminum composite panel to maintain product quality, brand image and customer satisfaction. Uneven panels can result in structural and visual imperfections, as well performance loss detracting from the overall strength and dependability of the finished product. Because it standardizes the entire production process, Pufeier is able to provide quality panels that are in line with industrial standards and surpass customer's requirements. Efficiency and economy: Best practice manufacturing practices also result in cost efficiency, limited waste, defined processes, and greater competitiveness.

Common Problems and Solutions in the Production Welding Process of Aluminum-plastic Composite Panels

Typical problems from the production of aluminum composite panels are delamination, surface quality and appearance problems, color mismatch (shade variation), dimensional issues. To overcome these problems Pufeier uses Proactive measures such as material testing, quality controls, production monitoring and corrective actions. By catching possible problems right away and taking corrective steps, we reduce risk and maintain a high level of quality control on our panels. Continual Performance Improvement measures, staff training, and feedback mechanisms are important steps to deal with some of the most common manufacturing problems and ensure consistent quality.

How do manufacturers keep consistency of the Aluminum composite Panel?

Aluminium composite panel manufacturers provide a high degree of consistency and quality through product regulation, employee education, manufacturing controls, improving processes and implementing an effective quality-driven system. Pufeier uses technology and customer feedback to research, test and refine metalworking processes that streamline production while reducing costs. By focusing on consistency throughout the design process, our product line is sure to meet all of our client’s needs.

Material: Fabric

*Note: This cushioned cotton slipper does not have non-slip soles. We are dedicated to delivering superior products through an excellent product development process, taking the industry into account and setting new standards in the aluminium composite panel sector.

Table of Contents

- How Aluminum Composite Panel Manufacturers Do Quality Control With aluminum?

- Key Factors

- The Importance of Consistency in the Production of Aluminum Composite Panels

- Common Problems and Solutions in the Production Welding Process of Aluminum-plastic Composite Panels

- How do manufacturers keep consistency of the Aluminum composite Panel?

- Material: Fabric