Black aluminum composite panels are widely used in many buildings today. These look very slick and are a deep black in color which really helps them pop. They are manufactured by laminating a plastic-core, such as polyethylene or polystyrene, between two thin sheets of aluminium. This combination lends the sheets strength, yet still lightness. These sheets can be cut, bent and molded due to their special construction. That’s why people like using them on walls and ceilings and signs. Our company, Pufeier, produces high quality black aluminium composite sheets that are long lasting and look great. The sheets are weather resistant, so they don’t fade or become damaged quickly. They would pick up Pufeier’s sheets, and some its competitors’, they explained, because it marries strength with style in one sheet. If you find a new building with the modern-looking facade but it is extremely shiny and black, it’s probably utilizing a black aluminum composite sheet like ours. For those interested in different options, we also offer Solid Finishes aluminum Composite plate - 4mm x 1220mm x 2440mm which provide excellent durability and aesthetic appeal.

Black aluminium composite panels blend well with the modern buildings partly because of the several reasons. For one, they look very tidy and sleek. The black color provides a strong and sophisticated contrast on any building. It can do wondrous things to make a small building look bigger or a simple design pricier. Since these sheets are lightweight, they do not put much additional load on walls or structures, a crucial factor in tall buildings. And one great things is that these sheets won’t rust or be broken by the rain and sun quickly. For example, if you have a building near the ocean, salty air can make many different metals rust. But the black aluminum composite sheets of Pufeier resist this issue reasonably well. And these sheets can be molded into desired shapes without breaking. Which means architects can play with new styles without fear the material will break. The sheets also help in warm or cool buildings by providing insulation. So, they help save energy. Fireproofing is necessary on some building. Our sheets can be manufactured with special cores that slow down fire, which enhances safety. Architects hate dirty materials, and these sheets clean up with a fast wash to be good as new. It is because of all these benefits that black aluminium composite sheets are a favourite of many contemporary buildings. Pufeier ensures that everyone sheet reaches these high requirements, and this means you will get the best product for your project. Additionally, we provide Metallic Finishes aluminum Composite plate - 0.4cm x122cm x 244cm that add a unique visual effect to modern architecture.

Even so, black is a difficult color to use for cladding and if not installed correctly problems can arise. One common problem is failing to properly prepare the surface before laying the sheets down. If the wall or frame is dirty or imperfect, the sheet might not adhere properly and could appear lumpy. At Pufeier, we tell installers to first clean and smooth the surface. Another issue is that the sheets may have been cut using incorrect tools. Dull blades or the wrong saws can create rough edges or even fractures. This weakens the sheets and makes them less beautiful. We would suggest sharp, dedicated tools for cutting this material — don’t ruin your good scissors! At others, the installers do not leave enough space for the sheets to expand and contract with temperature variations. Black sheets heat up in the sun and may expand slightly. The sheets, without space to flex, may buckle or distort. We suggest your installer leave that does has a natural expansion and contraction in its raw state. Moreover, incorrect fixing procedures can lead to sheets being damaged. Dents or cracks can form if screws or nails are too tight. This is avoided by using the correct fasteners and puting them in correctly. If the installers hurry or don’t adhere to the instructions, the final work may appear shoddy and sag or buckle prematurely. At Pufeier, our experience has taught us that training and patience are essential. But putting in the time to learn the stuff and follow good practices goes a long way. Careful installation of black aluminium composite sheets ensures buildings look good and are preserved for years.

Second, the thickness of the sheets. Black aluminium composite panels generally include two thin layers of aluminium between relatively thicker plastic or other material. The thickness of these layers impacts the strength and durability of the sheet. At Pufeier, we ensure our sheets have the correct thickness in order to make them strong yet still light. The thickness of this pad can be measured with a measuring instrument for comparison with the product description before you buy it. For example, our standard 4mm aluminum Composite plate - 4mm 1220mm x 2440mm (122cm x 244cm) meets these criteria perfectly.

In case you wish to purchase a large quantity of black aluminum composite sheets, it is crucial that you are aware on how to get hold of the real and authentic product. Bedding made from low thread counts may look nice at first, but can break down easily or the color can fade. At Pufeier, we know it can be challenging to choose sheets and for this reason, we are here with simple tips to help wholesale buyers distinguish black aluminium composite sheetwhich is real,and which isn’t.

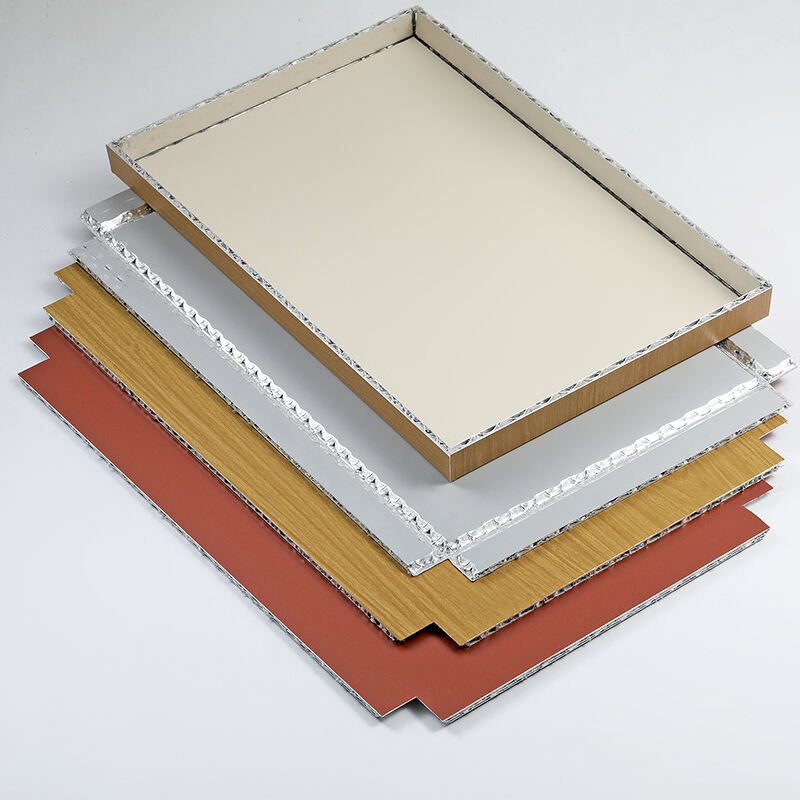

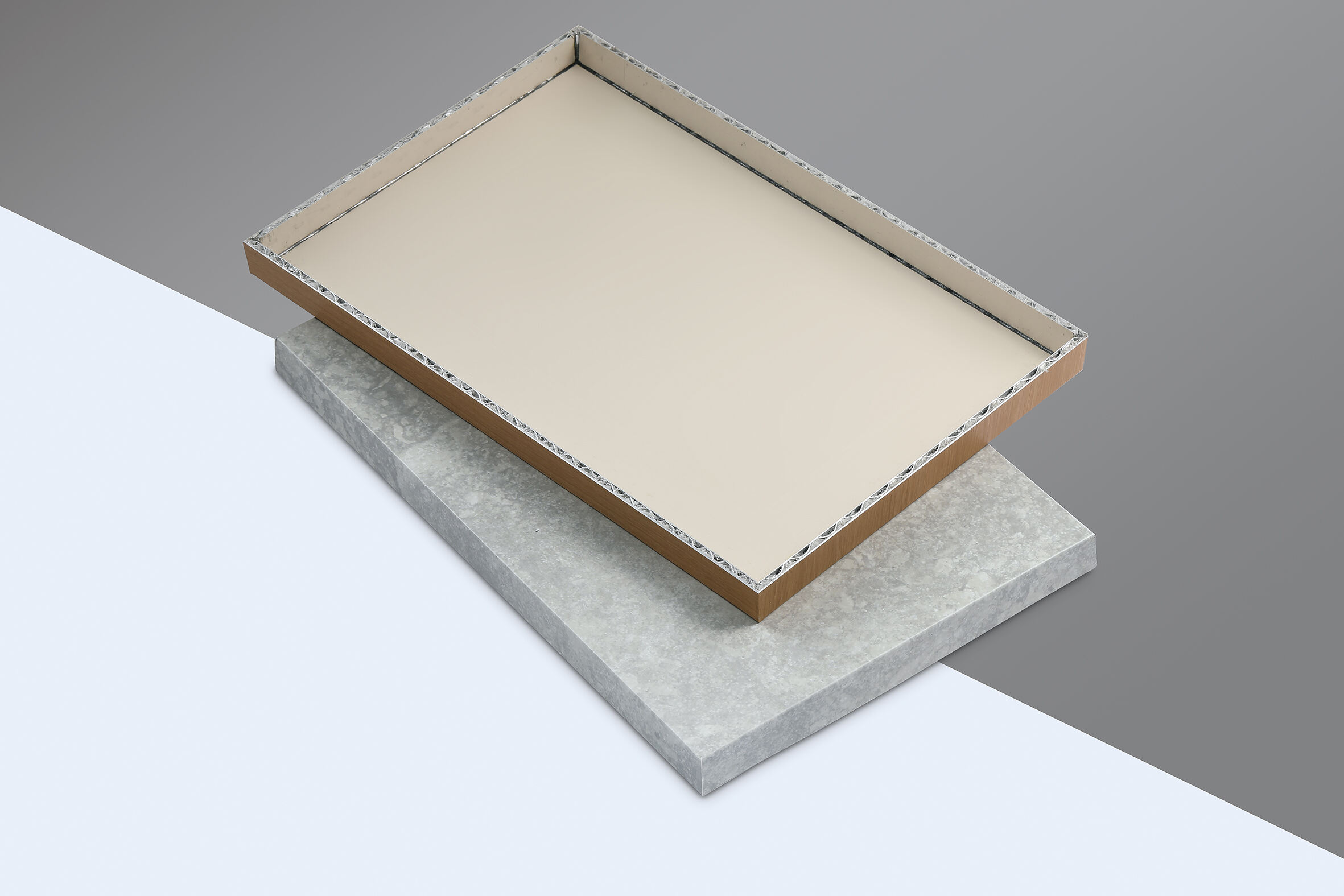

The layers of the sheet Take a look at the layering of your sheet first. True aluminum composite sheets are actually 3 materials in one: two thin layers of aluminum absolutely bonded to a polyethylene core. The core may be constructed of polyethylene or a fire retardant material. If they feel soft or flimsy, these are not real sheets. You might consider trying to bend the sheet if it's pliable instead of all fragile and likely to crack or break.

Second, try the color and coating. The true black aluminium composite material is smooth on one side and has a gloss matte finish on the other, providing an image that shines and prevents damage to images being placed within. If the color appears dull or uneven, or if the coating seems to peel away, it could be a counterfeit or inferior-quality sheet. “Our sheets from Pufeier have always had a strong coating that remains both bright and smooth even after very long use.

We produce a wide range of aluminum products—including 3D panels, honeycomb panels, veneers, and fasteners—supplying major corporations such as China State Construction and Gold Mantis across 80+ countries.

Our integrated factory and dedicated R&D center enable full control over innovation and manufacturing, supported by a daily production capacity of 10,000 square meters, ensuring both custom solutions and large-scale output.

With over three decades of focused expertise in the metal aluminum plate industry, we have developed deep technical knowledge and a proven track record of delivering high-quality products and reliable service to clients worldwide.

Every product undergoes strict quality control from raw materials to final inspection, ensuring premium performance and compliance with international standards, backed by over $10 million in annual export revenue and a strong global distribution network.