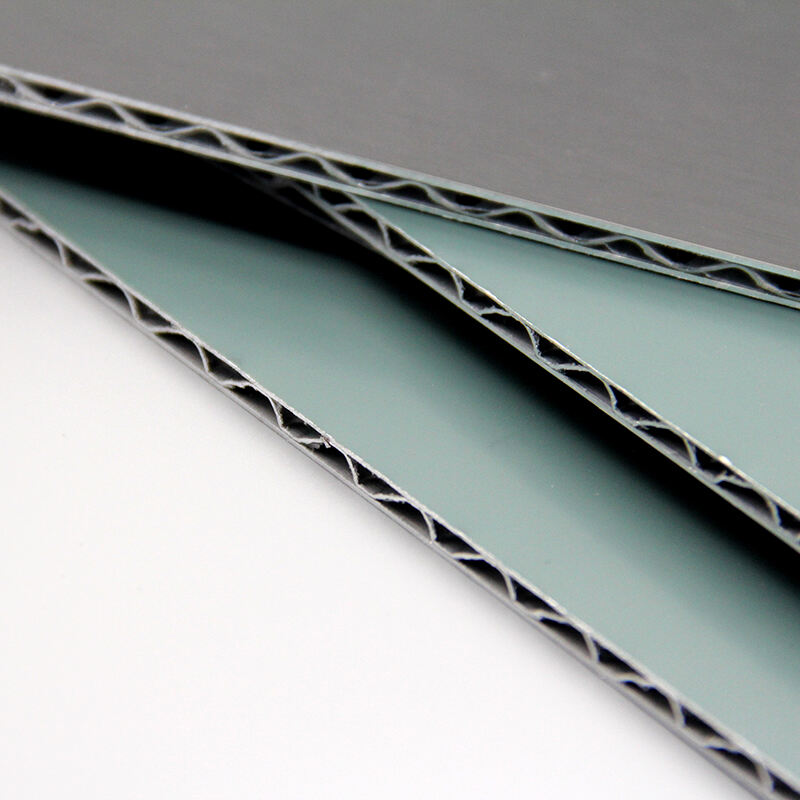

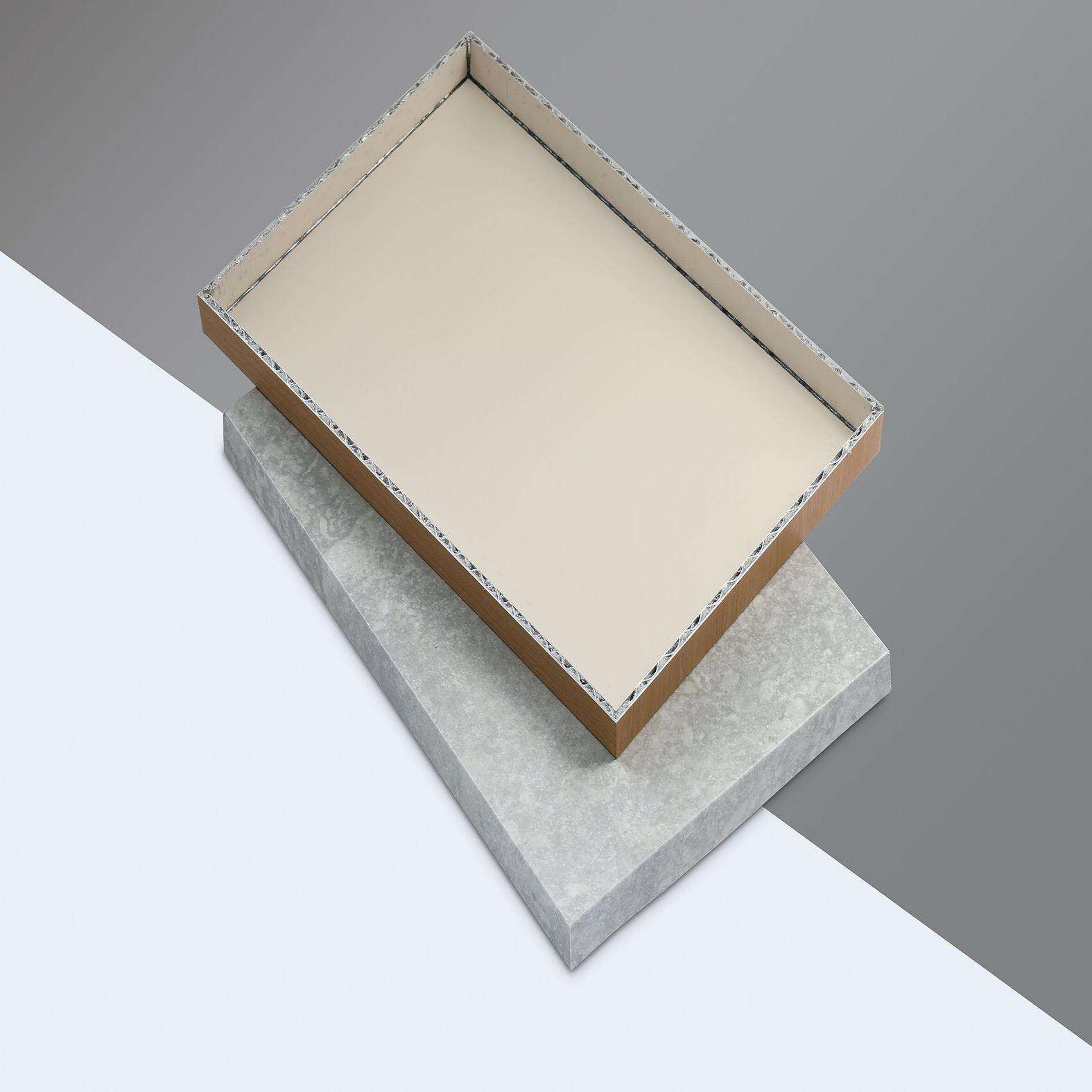

Aluminum sandwich panels are special construction material that extracted mostly form the two metal based and commonly used; where two thin hewed sheets made from aluminium likes surface of normal thickness frame which mainly contributes to total manufacture. The core can be constructed from various materials such as foam or honeycomb formations. “These panels are really light but they’re very strong. They can be carried and installed with ease, and so builders have used them for walls, ceilings and roofs in buildings. They are also heat and cold blockers that help in keeping the inside temperature stable. Even better, aluminum doesn’t rust, so these panels can stay up a long time without damage and even the rain or snow. Pufeier puts care and skill into these panels to make sure they’re used for many purposes, whether on small projects or big construction sites.

It can be hard to purchase as many aluminum sandwich panels as you need, especially if quality is of the essence. First, consider what you need them for. Are they for a building which is to be very strong, or are they only ornamental? It’s also all about the core inside of the panel. So while foam cores are lighter and more effective at keeping the heat out, honeycomb arrays instead provide strength and support. Thickness is another consideration to look out for. It is thicker panels that tend to stand up to wind and other forces the best. You also need to consider the surface finish. A shiny coating over some panels protects the panel from scratches and from weather. If you’re buying a lot, it’s wise to ask for samples first. That way you can feel the panels and take a look at them before making your decision. Each production process at Pufeier is strictly monitored for every process. We put the panels through tests to make sure they are sturdy and fit your needs. Occasionally people forget about the edges. Water can seep into the panel and damage it from the inside out if edges aren’t sufficiently sealed. So, just ask what the sealing process was. Quality is not everywhere about how the panel looks ascending, but about how it performs background over time. The right panels will require less repairs and last longer. Take your time buying in bulk because bad panels can lead to big problems down the road. With Pufeier’s panels, you are getting products produced with at least a bit of care and years of expertise that can keep you from making mistakes and provide what exactly it is that you want.

When looking for aluminium sandwich panels supplier quality is about more than just price. There are many places that sell these panels, but not all are good. You need a supplier that gets what you're looking for and will get the panels to you on time. And sometimes, what suppliers say will be in a box isn’t necessarily what ends up being put in that box. That’s frustrating and costly. Pufeier tries hard to be worthy. We are good at communicating with you and ensuring that your order is what you want. Shipping is another important point. Panels are subject to damage during transport if not handled well. A strong supplier provides good packaging and shipping. Also, consider the company’s experience. If they know the industry inside out, they can also offer guidance, such as in this case about which panel is best in certain weather or building types. Some providers sell only minuscule amounts, however, so if you are seeking wholesale quantities in this stream of the market, look for companies that have sufficient inventory to fill larger orders without delay. Pufeier has the capacity to make large orders and keep consistent quality with each panel. Good service Another indicator of a good supplier is their customer service. When you have questions or issues, you need answers that are timely and helpful. Suppliers sometimes vanish after you have paid. That’s where it pays to go with a company that backs up its products and provides support when you need it. In the end, dealing with the right supplier will save you time, money and grief. Pufeier is honored to be a trustworthy partner of businesses for durable aluminum sandwich panels.

The world of construction materials is increasingly moving towards aluminium sandwich panels. These panels are preferred by many builders and companies for the fact that they have so many good features. A sandwich panel typically consists of three layers: two strong aluminium (or other metal) sheets on the outer, and a light but tough core in between. This type of construction allows the panel to be strong and light simultaneously. Due to this, aluminium sandwich panels are lightweight and easy to handle during installation, thus reducing backing rig time on the construction site. At Pufeier, many customers express that they choose aluminum sandwich panels for use in their projects as the panels have good heat insulation. This is because they help to keep buildings warm in winter and cool in summer, keeping homes and offices comfortable and saving on energy. Another reason that these panels are popular is because they provide good protection to buildings against weather such as rain, wind and sun. They do not rust or break easily, and can last a long time without the need for much repair. This makes them a good option if you want your buildings to last decades. Aluminium sandwich panels also look good and clean, smooth and polished surfaces. It makes buildings modern and pretty. These panels are often favored by architects and designers to clad their building with something that is stylish. In all these respects, aluminium sandwich panels are your prime choice for large-scale projects requiring a lot of material. The purchase of these panels in bulk from reliable and responsible distributors such as Pufeier also means builders can get fair rates while maintaining they have sufficient materials to complete their work on time. The panels are becoming better known, and more and more people are opting to use them because they are strong, light, energy-efficient, weather-resistant and nice-looking. That, in short, is why aluminium sandwich panel are trending in wholesale building materials.

If you purchasing aluminium sandwich panels in bulk, it is crucial to ensure that the panels are high quality. Well-made panels will be strong, safe and long-lasting. We always tell our buyers at Pufeier to ensure that they follow a few important points before buying panels in bulk. First, examine the materials of the panels. The outside aluminum skin need to be constructed from quality aluminium by no means lower than 0.5mm thickness clean with out any dimples or scraps. The panel’s core should be a tough foam or other strong substance that will help keep the panel lightweight yet sturdy. The panel may break or deform when the core is thin. Then, take a look at the panel thickness. Thicker panels generally indicate better insulation and more protection. But the thickness has to best suit your project, so it’s good to consult with specialists at Pufeierwho can direct you to a suitable thickness. Another thing to consider is search for certification or test reports. Reputable suppliers will have documentation that attests their panels comply with safety and quality requirements. These are tests that demonstrate that the panels can withstand fire, wind and water with no issues. Always request these papers from the supplier before you make a purchase. Also, inquire about the coating on the aluminium sheets. A quality coating shields the panels from rust and sun-fading. At Pufeier, we apply special coatings that maintain the new look of panels over many years. You can also request for samples panels to test the quality of the material yourself before committing to a large order. Lastly, make sure you are hiring a reputable supplier that has good reviews and experience. Pufeier has served many clients from home and abroad with excellent products and reliable service. Purchasing through a reputable company minimizes the chances of receiving substandard material and will help your building project run smoothly. If you follow these steps, you can ensure that the wholesale aluminium sandwich panels you purchase will be strong, safe and a perfect fit for your building requirements.

With over three decades of focused expertise in the metal aluminum plate industry, we have developed deep technical knowledge and a proven track record of delivering high-quality products and reliable service to clients worldwide.

We produce a wide range of aluminum products—including 3D panels, honeycomb panels, veneers, and fasteners—supplying major corporations such as China State Construction and Gold Mantis across 80+ countries.

Every product undergoes strict quality control from raw materials to final inspection, ensuring premium performance and compliance with international standards, backed by over $10 million in annual export revenue and a strong global distribution network.

Our integrated factory and dedicated R&D center enable full control over innovation and manufacturing, supported by a daily production capacity of 10,000 square meters, ensuring both custom solutions and large-scale output.